Laminate & Metal Tubes

Round Laminate Tubes

Laminate & Metal Tubes

Overview

Laminate and metal tubes offer superior barrier protection for a wide range of products including pharmaceuticals, oral care, cosmetics, food, and industrial applications. Their robust construction preserves product integrity and extends shelf life.

Available Volume

Typically available from 5ml to 270ml (0.17 - 9 fl oz).

Material

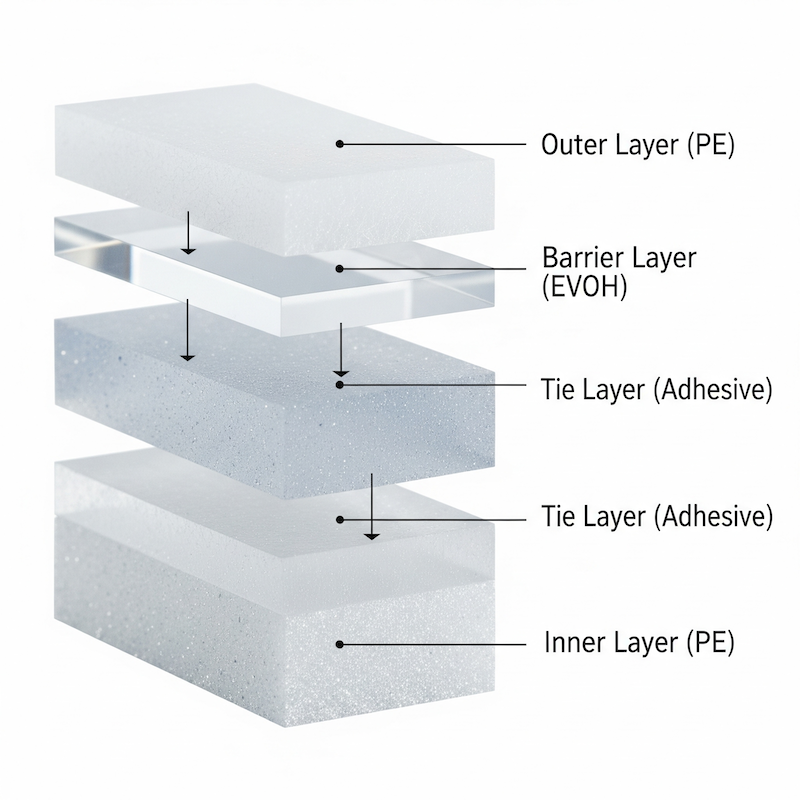

Laminate Tubes: Constructed from multiple layers of plastic, foil, and adhesive.

ABL (Aluminum Barrier Laminate): Features a thin layer of aluminum foil, providing an excellent barrier against light, oxygen, and moisture. Ideal for sensitive formulas like pharmaceuticals, toothpaste, and certain food products.

PBL (Plastic Barrier Laminate): Uses a plastic barrier layer (like EVOH) instead of aluminum. Offers good barrier properties while providing a 'bounce-back' quality similar to all-plastic tubes, making it visually appealing throughout its use. Often more recyclable.

Metal Tubes: Aluminum is the standard material for metal tubes, offering ultimate barrier protection. It is inert, non-toxic, and highly recyclable.

Benefits of Laminate & Metal Tubes

Superior Protection: Unmatched barrier against oxygen, light, moisture, and contaminants, preserving product efficacy and freshness.

Hygienic & Safe: The non-porous and non-reactive nature of aluminum and laminate barriers prevents contamination and interaction with the product.

Dead-Fold Characteristic: (ABL & Aluminum) Tubes stay collapsed after squeezing, which prevents air from being drawn back in, reducing oxidation and contamination.

High-End Decoration: Allows for photorealistic printing, metallic finishes, and a premium look and feel on the shelf.

Tamper Evidence: Often supplied with a sealed nozzle that must be pierced by the cap, providing clear tamper evidence for the consumer.

Eco Friendly & Sustainability

Aluminum tubes are infinitely recyclable with high recycling rates globally.

Innovations in PBL (Plastic Barrier Laminate) tubes have led to versions that are recyclable within standard HDPE or PP plastic streams.